IoT App Development

Editorial Team

23 Dec 2025

Introduction

In 2026, connected devices are everywhere—from smart meters and factory robots to connected cars and wearable health trackers. Businesses planning a connectivity strategy often encounter two closely related terms: Internet of Things (IoT) and Machine to Machine (M2M). While they are sometimes used interchangeably, IoT and M2M have distinct architectures, purposes, and business impacts.

This guide explains what IoT and M2M mean, how they differ, where they overlap, and which approach makes sense for your organization. With clear examples, diagrams, trends, and decision points, it will help you choose the right connectivity foundation for your next digital initiative.

What Is IoT?

The Internet of Things (IoT) refers to a network of physical devices—sensors, machines, vehicles, appliances—that are connected to the internet and exchange data with cloud platforms and other systems. These devices are usually equipped with sensors, connectivity modules (Wi Fi, cellular, LPWAN, etc.), and software that enables remote monitoring, control, and analytics.

IoT systems typically send data from devices to a cloud platform, where it is stored, processed, and integrated with other applications and AI/ML services to produce dashboards, alerts, automation rules, and business insights. Examples include smart thermostats, connected logistics fleets, smart city lighting, and industrial IoT solutions for predictive maintenance.

What Is M2M?

Machine to Machine (M2M) communication describes direct data exchange between devices without (or with minimal) human intervention. Traditionally, M2M systems use cellular or wired networks to connect specific machines—for example, a vending machine sending inventory data to a central server, or a utility meter transmitting readings to a billing system.

M2M deployments often rely on point to point or hub and spoke connections, using specialized hardware modules and private networks. They prioritize reliability, low latency, and secure, closed communication over broad internet connectivity or open ecosystems. As a result, M2M is widely used in industrial automation, SCADA systems, telematics, and remote asset monitoring.

Key Differences Between M2M and IoT

Although IoT builds on many of the same foundations as M2M, there are important differences in architecture, scalability, data usage, and business scope.

| Aspect |

M2M |

IoT |

| Primary Focus |

Direct device to device communication for specific tasks |

Large scale device connectivity with cloud integration and analytics |

| Connectivity |

Often private cellular, wired, or closed networks |

IP based networks (Wi Fi, 4G/5G, NB IoT, LoRaWAN, satellite) via the internet |

| Architecture |

Point to point or hub and spoke; limited interoperability |

Layered architecture with devices, gateways, cloud platforms, APIs |

| Scalability |

Optimized for a fixed, limited number of nodes |

Designed to scale to thousands or millions of devices |

| Data Handling |

Local or server side; limited aggregation and analytics |

Centralized data lakes, big data, AI/ML for real time insights |

| Openness |

Proprietary hardware and closed ecosystems |

Open APIs, integrations with ERP, CRM, analytics platforms |

| Typical Use Cases |

Industrial automation, telemetry, SCADA, fleet tracking |

Smart cities, consumer IoT, industrial IoT, connected products |

In short: M2M focuses on connecting machines so they can perform specific functions autonomously, while IoT extends that connectivity into the cloud to enable cross system integration, rich analytics, and large scale automation.

Purpose of IoT & M2M

Purpose of IoT

- Collect real time data from diverse devices and environments and centralize it in cloud platforms.

- Enable analytics, AI, and automation to optimize operations, reduce costs, and create new digital services.

- Provide user friendly interfaces (dashboards, mobile apps, APIs) for decision makers, partners, and customers.

Purpose of M2M

- Ensure reliable, low latency communication between machines to automate specific processes or telemetry flows.

- Reduce human intervention for routine tasks like meter readings, status checks, or alarm notifications.

- Improve operational efficiency and uptime using direct, tightly controlled connections within a defined system boundary.

Diagram for IoT & M2M

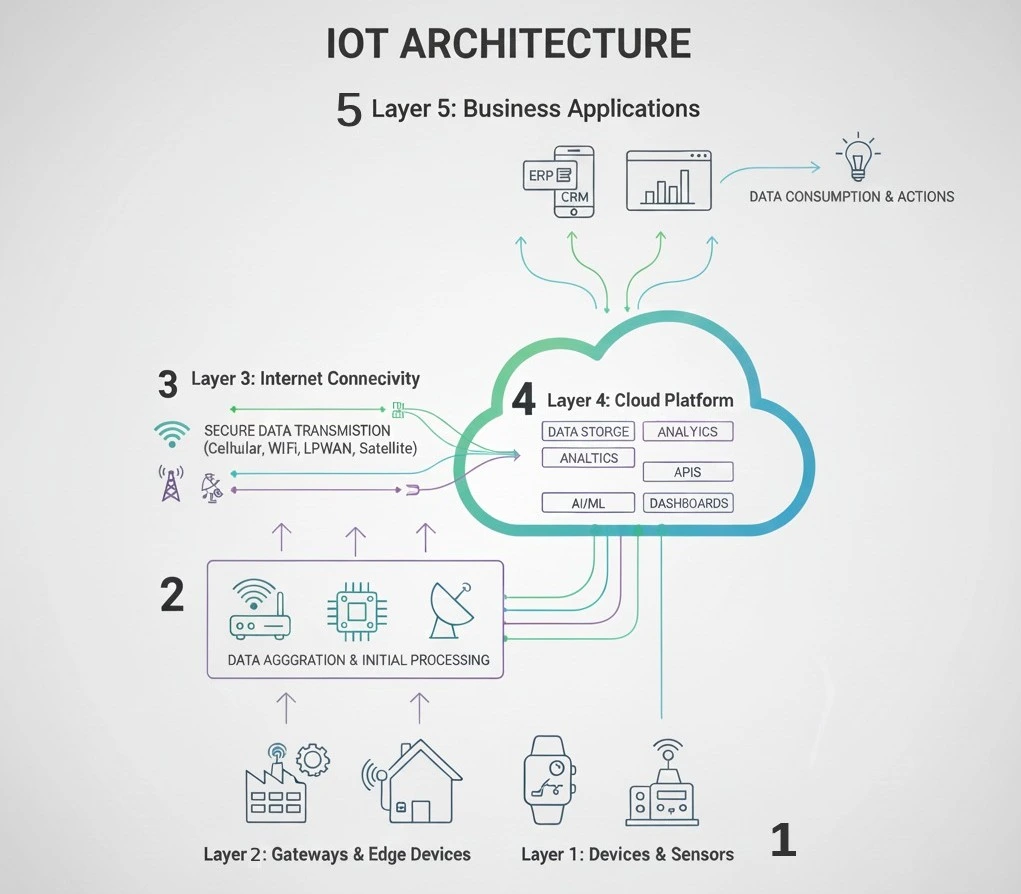

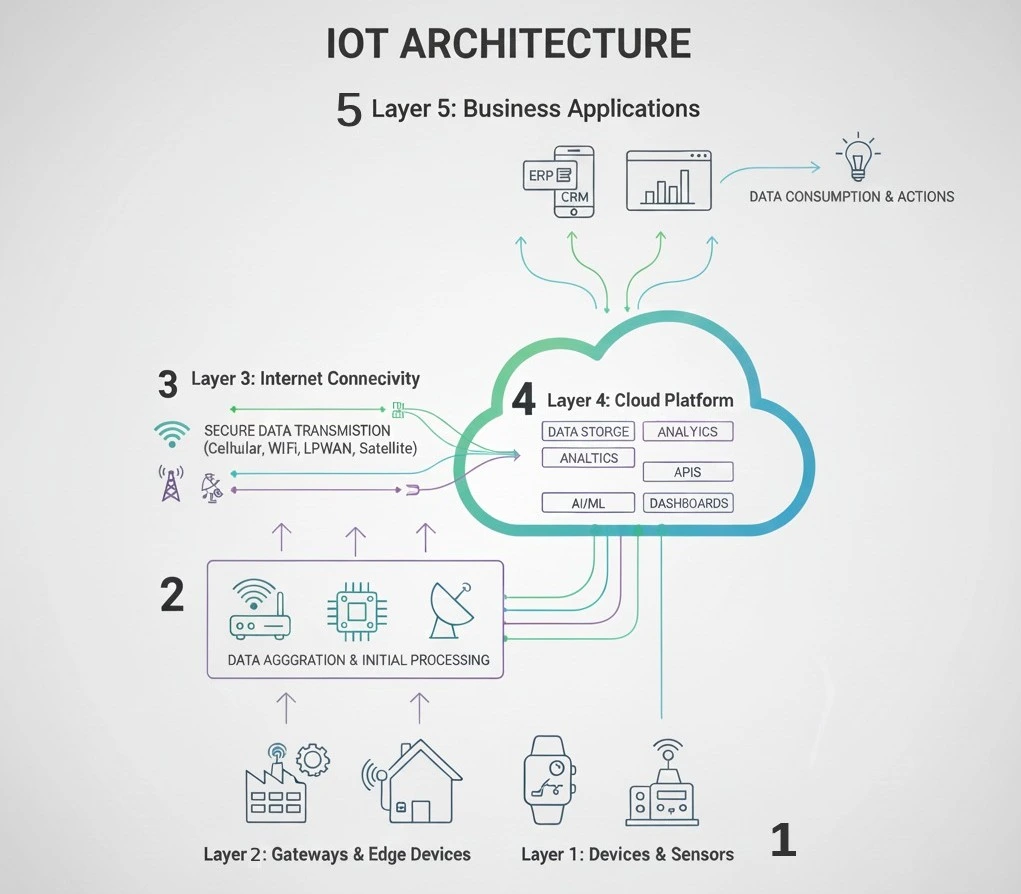

IoT Architecture Diagram

- Layer 1: Devices and sensors (e.g., sensors on equipment, smart meters, wearables) gather data.

- Layer 2: Gateways or edge devices aggregate data and perform initial processing.

- Layer 3: Internet connectivity (cellular, Wi Fi, LPWAN, satellite) transmits data securely to the cloud.

- Layer 4: Cloud platform with data storage, analytics, AI/ML, APIs, and dashboards.

- Layer 5: Business applications (ERP, CRM, mobile apps, web portals) consume data and trigger actions.

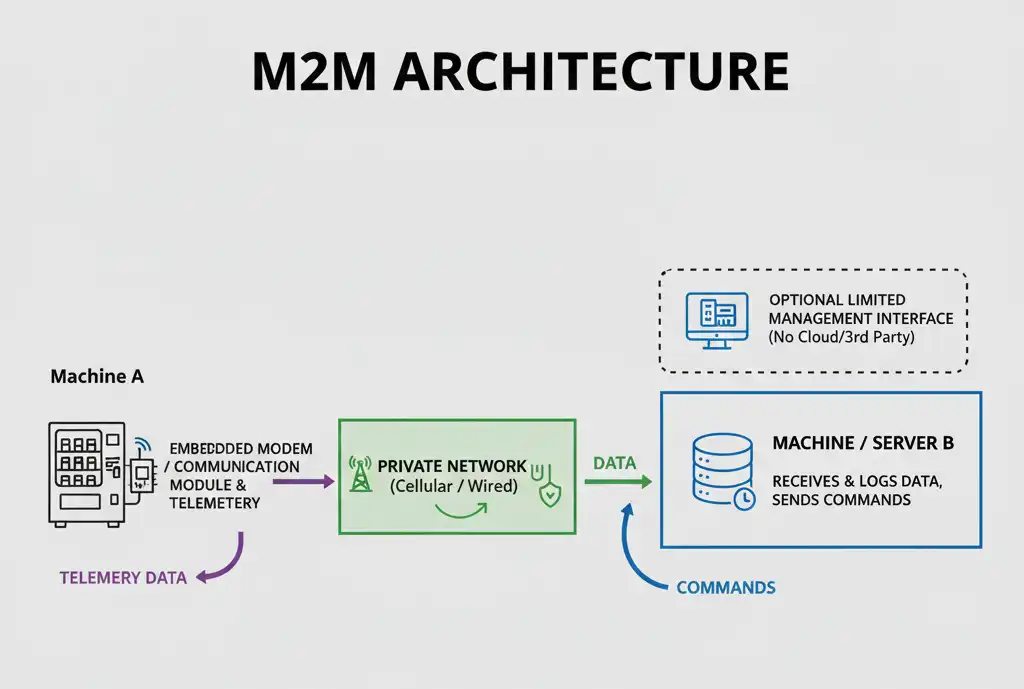

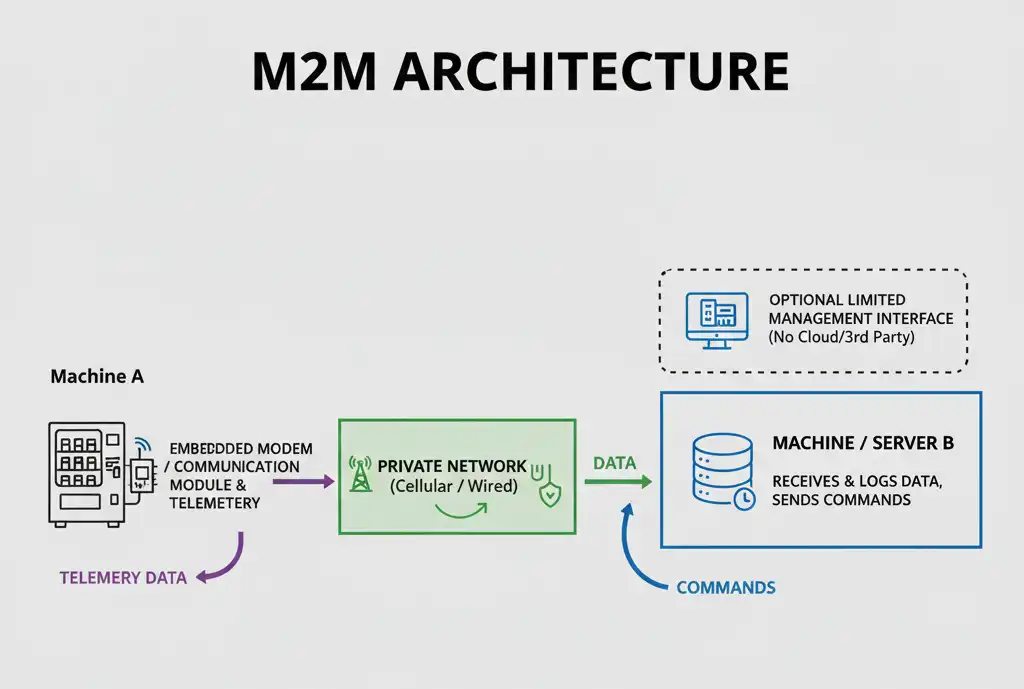

M2M Architecture Diagram

- Machine A: Embedded modem or communication module collects telemetry (e.g., from a vending machine or industrial controller).

- Network: Private cellular or wired connection sends data to a central server or directly to Machine B.

- Machine/Server B: Receives data, logs it, and may send commands back to Machine A.

- Optional: A limited management interface for operators, often without broader cloud or third party integration.

Key Trends in IoT and M2M in 2026

- Convergence of IoT and M2M: Modern deployments often start with M2M style connectivity at the edge and then connect those networks to IoT platforms for analytics and orchestration.

- 5G and LPWAN growth: 5G, NB IoT, LTE M, and LPWAN technologies like LoRaWAN enable higher device density, lower latency, and longer battery life.

- AI at the edge: Edge computing and embedded AI allow devices to make local decisions quickly, reducing bandwidth and enabling real time control.

- Stronger security and device management: Standardized frameworks for identity, encryption, over the air updates, and eSIM/eUICC reduce operational risk for massive fleets.

- Vertical specific solutions: Pre built IoT/M2M platforms for logistics, utilities, manufacturing, healthcare, and agriculture accelerate time to value.

IoT or M2M – What Does Your Business Need?

Choosing between IoT and M2M (or combining both) depends on your objectives, scale, and integration needs.

You may lean towards an M2M centric approach if:

- You need highly reliable, low latency communication between a defined set of devices (e.g., industrial control systems, SCADA, elevator alarms).

- You operate in environments where internet access is restricted or where closed networks are mandatory for safety or compliance.

- Your use case focuses on monitoring and control rather than broad analytics or external integrations.

You may favor an IoT centric approach if:

- You want to connect many different device types and scale to thousands or millions of endpoints, such as smart city deployments or global fleets.

- You need centralized data, dashboards, and integration with cloud analytics, AI/ML, ERP, or CRM systems to create new services or business models.

- You require remote device management, firmware updates, and the ability to expose APIs to partners, customers, or developers.

In practice, many enterprises deploy hybrid architectures where M2M handles time critical local interactions, and IoT platforms consolidate data and orchestrate higher level workflows. For example, a factory may use M2M links between PLCs on the shop floor but push aggregated data into an IoT platform for predictive maintenance and enterprise dashboards.

Examples for IoT and M2M

IoT examples

- Smart home systems: Connected thermostats, lights, and security cameras controlled via mobile apps and cloud dashboards, with usage data analyzed for energy savings.

- Smart city lighting: Street lights with sensors and wireless connectivity that adjust brightness based on traffic and daylight, and report faults to a central IoT platform.

- Connected fleet management: Trucks with GPS, fuel, and engine sensors sending data to a cloud platform for route optimization, driver behavior analytics, and predictive maintenance.

- Smart agriculture: Soil moisture and weather sensors sending data to an IoT platform that automatically controls irrigation and provides yield forecasts.

- Remote health monitoring: Wearables and home medical devices (heart rate, glucose, blood pressure) streaming data to healthcare providers for continuous monitoring and alerts.

M2M examples

- Utility smart meters: Electricity or gas meters that periodically send consumption data over cellular networks directly to the utility’s billing server, with no cloud analytics layer.

- Vending machines with telemetry: Machines that automatically report stock levels and faults to a central system, triggering refills or maintenance visits.

- Industrial PLC–SCADA communication: Programmable logic controllers on a factory line exchanging signals with a SCADA system to start/stop equipment and raise alarms in real time.

- Elevator and lift monitoring: Elevator controllers sending status and error codes over a private network to a building management system for rapid service dispatch.

- Vehicle telematics units: Embedded modules in vehicles transmitting location, engine status, or crash alerts directly to a control center, often over closed cellular M2M links.

These pairs show the pattern: IoT examples typically involve internet/cloud connectivity, dashboards, and analytics, while M2M examples focus on tightly scoped, point to point machine communication.

Conclusion

IoT and M2M are closely related technologies that both enable machines to communicate without human intervention, yet they serve different strategic purposes. M2M excels at reliable, point to point communication in closed environments, making it ideal for specific industrial and telematics scenarios. IoT extends that foundation by adding internet connectivity, cloud platforms, and open integration, turning device data into a scalable resource for analytics, automation, and new digital services.

By understanding the differences in connectivity, architecture, scalability, and data usage, businesses can choose the right mix of IoT and M2M for their needs. Whether you are modernizing legacy equipment, building a smart product line, or launching a new connected service, clarifying where you need simple machine level automation and where you need cloud driven insight will help you design a future ready connectivity strategy for 2026 and beyond.

Frequently Asked Questions (FAQ)

IoT connects devices through the internet to cloud platforms for advanced analytics and automation, while M2M connects devices directly for specific, localized communication tasks.

IoT uses internet-based protocols and various wireless networks, whereas M2M typically relies on private cellular or wired networks with lower latency.

IoT powers smart homes, connected cars, healthcare wearables, and smart cities; M2M is widely used in industrial automation, remote monitoring, vending machines, and utility meters.

IoT leverages cloud and edge computing for handling big data and AI-powered insights, while M2M processes smaller datasets locally, focusing on immediate device-to-device communication.

Yes, IoT systems often include user interfaces like dashboards and apps, while M2M systems operate mostly autonomously with minimal human interaction.

IoT is designed for large-scale deployments involving millions of devices, offering more flexibility and integration, whereas M2M is typically limited to smaller, specialized networks.

Yes, many modern systems use M2M connectivity at the edge for reliable device communication, coupled with IoT platforms in the cloud for data aggregation, analytics, and business integration.

Choose M2M for simple, direct machine communication in closed environments; choose IoT for scalable, internet-connected, data-driven applications requiring integration and analytics.